If you’re involved in fabrication, construction, or metalwork, chances are you’ve encountered 7018 welding rods. Widely recognized for their versatility and reliability, 7018 rods are a go-to choice for welders across industries. From bridges and buildings to pipelines and shipbuilding, 7018 electrodes play a crucial role in creating strong, high-quality welds.

In this blog, we’ll break down everything you need to know about 7018 welding rods their composition, advantages, applications, and tips for using them effectively.

What Are 7018 Welding Rods?

The 7018 welding rod is a low-hydrogen, iron powder-coated electrode used in Shielded Metal Arc Welding (SMAW), commonly known as stick welding. The name “7018” is not just a product number it tells you a lot about its properties:

- 70: The weld it creates has a tensile strength of 70,000 psi.

- 1: It can be used in all positions (flat, horizontal, vertical, and overhead).

- 8: Refers to the type of flux coatingn low hydrogen and iron powder. It improves arc stability and deposition rate.

Composition and Coating

7018 rods are classified as low-hydrogen electrodes. The low hydrogen content in the flux minimizes the risk of hydrogen-induced cracking in the weld metal. The coating also contains iron powder, which increases deposition efficiency, making the rod ideal for heavy welds.

The core wire is typically a mild steel alloy, while the flux coating includes:

- Calcium carbonate

- Calcium fluoride

- Iron powder

- Binder materials

The coating helps stabilize the arc, control slag formation, and improve the overall quality of the weld.

Key Advantages of 7018 Welding Rods

1. High Strength and Ductility

The welds produced with 7018 rods offer high tensile strength (70,000 psi) and excellent ductility. This makes them suitable for structural applications where welds need to withstand heavy stress or vibration.

2. Smooth, Clean Welds

7018 rods produce a smooth arc and leave behind minimal spatter. The resulting welds have a clean, uniform appearance with good bead profile—ideal for jobs where aesthetics and strength both matter.

3. All-Position Welding

Whether you’re welding flat surfaces or working overhead, 7018 rods can handle it. Their usability in all positions gives welders flexibility, especially on large construction sites where repositioning heavy components is not practical.

4. Reduced Hydrogen Cracking

The low-hydrogen coating greatly reduces the risk of cold cracking, especially in high-strength steels or thick materials. This makes 7018 ideal for critical structural joints.

5. Excellent Mechanical Properties

The weld metal exhibits good impact toughness, even at lower temperatures. This is important for structures exposed to outdoor environments, pressure, or seismic activity.

Common Applications of 7018 Welding Rods

Due to their strength and reliability, 7018 welding rods are widely used in heavy-duty and structural applications, including:

• Construction and Infrastructure

- Bridges

- Buildings

- Structural steel frames

• Pipeline Welding

- Oil and gas pipelines

- Water pipelines

- Pressure vessels

• Shipbuilding and Marine

- Hull welding

- Structural supports

- Deck fittings

• Heavy Equipment Manufacturing

- Excavators

- Cranes

- Industrial machinery

• Repair and Maintenance

- Fixing cracks in structural components

- Reinforcing aging steel infrastructure

- Joining different thicknesses of metal

How to Use 7018 Welding Rods Effectively

Using 7018 rods requires attention to storage and welding technique:

1. Proper Storage

7018 rods are moisture-sensitive due to their low-hydrogen coating. If they absorb moisture, hydrogen may enter the weld and cause cracking. To prevent this:

- Store them in a dry rod oven at 250°F to 300°F (120°C to 150°C)

- Use them within 4 hours of removing from the oven

- Avoid using rods that have become damp

2. Correct Polarity

For best results, use DC+ (Direct Current Electrode Positive) polarity. This provides deeper penetration and a stable arc. AC current can also be used but may result in less consistent welds.

3. Control Your Travel Speed

7018 rods have a slower freezing slag, which means they require controlled travel speeds. Moving too fast can result in poor penetration; moving too slow can lead to excessive buildup and slag inclusions.

4. Clean the Base Metal

Always clean the metal surface before welding. Remove rust, oil, paint, or mill scale to prevent contamination and ensure strong fusion between materials.

Limitations and Considerations

While 7018 welding rods are incredibly versatile, they do have some considerations:

- They require clean, dry conditions for storage and usage

- Not ideal for galvanized or heavily contaminated surfaces

- The slag can be a bit more difficult to remove than with some other electrodes

- They require a steady hand and precise technique, especially in vertical and overhead positions

Despite these, experienced welders often prefer 7018 because of the superior quality it delivers when used correctly.

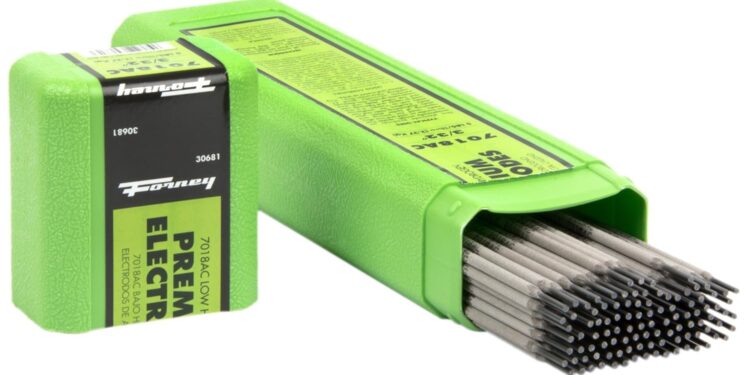

Choosing the Right 7018 Rod

7018 rods come in various diameters such as 1/8”, 3/32”, and 5/32”. The choice depends on:

- Material thickness

- Welding position

- Amperage range of your machine

Consult with welding supply professionals or manufacturers to ensure you select the right size for your project. Reputable brands ensure consistent quality, which is especially critical in structural applications.

Conclusion

Whether you’re constructing a skyscraper or repairing a farm gate, 7018 welding rods are a top choice for achieving strong, durable, and clean welds. Their low-hydrogen composition, high tensile strength, and versatility make them an essential tool in every welder’s toolkit.

By understanding how to use, store, and apply 7018 electrodes, you can improve weld quality, reduce failure risk, and ensure the long-term performance of your welded structures. For best results, always use rods from trusted manufacturers and follow proper welding practices.