The Evolution of Grinding Machinery: From Manual Techniques to Automated Precision

Grinding machinery has played a crucial role in shaping industries ranging from metalworking to manufacturing and construction. Over the centuries, grinding techniques have evolved from rudimentary manual methods to highly sophisticated automated systems. These advancements have led to improved precision, efficiency, and consistency, meeting the growing demands of modern industries.

According to a Grinding Machinery Market report, the industry is expected to grow significantly in the coming years.

Early Developments in Grinding Technology

The origins of grinding can be traced back to ancient civilizations, where rudimentary grinding stones were used to shape tools and weapons. The advent of hand-operated grinding wheels in the Middle Ages improved precision but remained labor-intensive.

The Industrial Revolution brought significant innovations, including powered grinding machines that utilized steam and later electrical power. These early machines enabled mass production and greater uniformity in metalworking and toolmaking. Innovations such as the cylindrical grinder, introduced by Joseph Brown in the mid-19th century, revolutionized grinding by allowing for high-precision machining of cylindrical surfaces.

The Rise of Mechanization and Efficiency

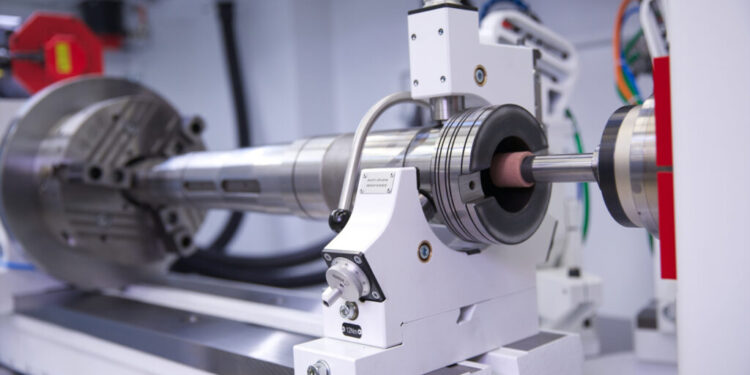

By the early 20th century, grinding machinery saw major advancements with the development of surface grinders, centerless grinders, and internal grinders. The introduction of high-speed steel and tungsten carbide grinding wheels improved cutting performance and durability.

The integration of hydraulic and pneumatic controls in the mid-20th century allowed for smoother operations, reducing human error and enhancing consistency. Automated feed systems and precision control mechanisms further improved grinding accuracy, catering to the needs of industries such as aerospace, automotive, and tool manufacturing.

The Digital Revolution and Smart Grinding Systems

The rise of computer numerical control (CNC) technology in the late 20th century transformed grinding machinery. CNC grinding machines enabled fully automated processes, minimizing manual intervention and achieving micron-level precision.

Industry 4.0 and the integration of IoT (Internet of Things) have further revolutionized grinding systems. Real-time monitoring, predictive maintenance, and AI-driven adjustments have optimized machine performance, reducing downtime and improving efficiency. These smart systems allow manufacturers to maintain high production rates while ensuring superior quality control.

Sustainability and Energy Efficiency in Grinding

As environmental concerns grow, modern grinding machinery has embraced sustainable practices. Advanced grinding wheel materials, including diamond and CBN (cubic boron nitride), reduce waste and enhance efficiency. Additionally, the use of eco-friendly coolants and lubrication systems minimizes environmental impact.

Energy-efficient motors and adaptive control systems help reduce power consumption, making grinding operations more sustainable. Recycling and reusing grinding byproducts have also gained traction, further promoting environmentally responsible manufacturing.

The Future of Grinding Machinery

Looking ahead, the future of grinding technology will be defined by further advancements in automation, artificial intelligence, and material science. Fully autonomous grinding systems equipped with AI-powered defect detection and real-time process optimization will continue to enhance production capabilities.

The adoption of robotics and collaborative automation will further improve safety and flexibility in grinding operations. The integration of blockchain technology for traceability in precision manufacturing could also revolutionize quality control and supply chain management.

Additionally, innovations in nanotechnology and ultra-precision grinding will enable the production of micro-components for medical, semiconductor, and aerospace applications. As industries continue to embrace digitalization and sustainability, grinding machinery will evolve to meet the challenges of modern manufacturing.

Conclusion

The evolution of grinding machinery from manual techniques to automated precision reflects the continuous advancement of manufacturing technology. With ongoing innovations in CNC automation, smart manufacturing, and sustainability, grinding remains a cornerstone of industrial production, delivering high-quality, efficient, and environmentally responsible machining solutions.